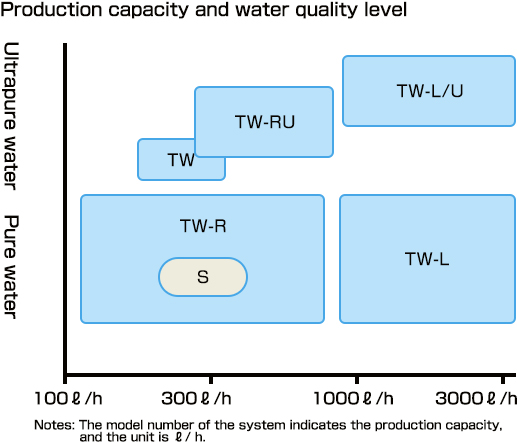

The MINIPURE Series is a package type system which produces pure water and ultrapure water easily by removing impurities in tap water.

It is possible to operate promptly after installation because it does not require complicated settings.

Compared to the systems made to order, the MINIPURE Series is superior in cost performance in every respect, such as short term construction schedule, low cost, and space saving.

It is possible to produce pure water and ultrapure water to meet the requirements of cleaning water for semiconductors, flat-panel display (FPD) substrate, or electronic substrate.

MINIPURE S-100

Features

- This model is a pure water system consisting of a non-regenerative type ion exchange column and filter.

Applications

- Pure water for the use of research laboratory and experimental laboratory.

MINIPURE S-100

(Dimensions: W420×D300×H1380)

MINIPURE TW-250/500

Features

- These models are ultrapure water systems consisting of multistage non-regenerative type ion exchange cylinders using MF membrane as final filter.

Applications

- Pure water for research and experimental laboratories, and cleaning water for the electronic industry.

MINIPURE TW-250

(Dimensions: W1000×D400×H2010)

MINIPURE TW-180R TW-300R/450R TW-600R/750R

Features

- These models are pure water systems consisting of activated carbon and RO membrane operated at low pressure, with low running cost. It is easy to install options such as column containing ion exchange resins or filter etc., which enables higher purity of pure water.

Applications

- Humidification water for clean rooms, boiler feed water, pure water for research and experimental laboratories, and cleaning water for the electronic industry.

MINIPURE TW-180R

(Dimensions: W350×D650×H1000)

MINIPURE TW-300RU(-P) TW-600RU(-P)/1000RU

Features

- These models are compact and package type ultrapure water systems consisting of two parts: one part produces pure water composed of RO membrane and ion exchange cylinder, while the other part produces ultrapure water composed of a UV sterilizer, ion exchange cylinder, and UF membrane.

- These models are designed to produce ultrapure water by removing ions, organic matter, and silica, as well as even bacteria and particles contained in tap water.

Applications

- Pure water for research and experimental laboratories, cleaning water for the electronic industry, flat-panel display (FPD) substrate, and semiconductor substrate

MINIPURE TW-300RU

(Dimensions: W1400×D600×H1800)

MINIPURE TW-L1000/2000/3000 TW-U1000/2000/3000

Features

- Since the production capacity is 1m3/h to 3m3/h, it is the most suitable for ultrapure water system for prototype production factories.

TW-L

- This is a pure water system consisting of membrane pretreatment, activated carbon, RO membrane, and ion exchange cylinder. It is easy to maintain and possible to produce pure water with less impurities by removing suspended solids, ions, organic matters and silica.

TW-U

- This model is an ultrapure water system consisting of TOC-UV used to decompose organic matters, ion exchange cylinder, and UF membrane. Using make-up water treated by TW-L as feed water, this system produces high-purity ultrapure water with all impurity concentrations reduced to ppb levels.

Applications

- Cleaning water for the electronic industry, FPD substrate, and semiconductor substrate.

MINIPURE TW-L/U2000

(Dimensions: TW-L2000: W1800×D1800×H2000)

(Dimensions: TW-U2000: W1200×D1500×H2000)

- Home

- Products & Services

- MINIPURE Series